We have helped many companies find solutions to save time and money while improving quality and reliability.

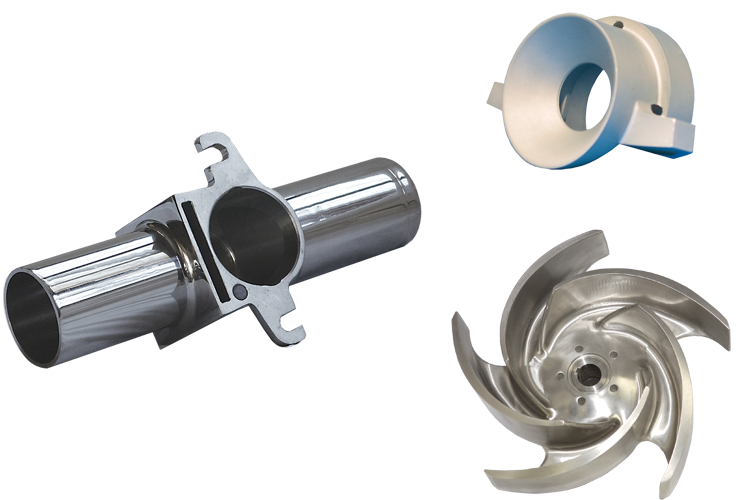

Investment castings reduce the high cost of your machined parts, weldments, fabrications and assembled mechanical components. From simple to complex shapes, investment castings provide you with the ideal solution for both your prototype and production requirements (whether high or low volumes).

LEARN MORE

Our Innovative Investment Casting Process

Wisconsin Precision Casting employs the latest in technology in our investment casting process to produce high quality mechanical component parts, cost effectively and on time. We’re constantly seeking new technologies and innovative ways to improve our investment casting process, our efficiencies, our quality and reduce our lead time.

VIEW OUR PROCESS VIDEO

Lost Wax Investment Casting Advantages

GREATER DESIGN FLEXIBILITY

SURFACE FINISHES 120 TO 150 RMS

WEIGHT REDUCTION

CLOSE TOLERANCES ±.005 INCH PER INCH

REDUCED MATERIAL COSTS

REDUCED OPERATION COSTS

ELIMINATES EXPENSIVE FABRICATIONS

LOW INITIAL TOOLING COSTS

Over 180 Different Alloys to Choose From

Our broad selection of alloys allows you to utilize a material that is best suited to your performance requirements. No other process offers as many alloys to choose from as the investment casting process. Our metallurgical and engineering staff is available at any time to answer any questions you may have about a particular alloy or any application.

CLICK THE BUTTON BELOW TO VIEW ALLOY SELECTION